Convincing Technology

- Direct servo drives on all cylinders

- Short changeover times due to computer aided settings

- Timed belt feeder

- Single roller glue unit can be adjusted while running

- Film position can be adjusted while running

- Maintenance free drives Infinitely variable delivery

- Heavy duty 1/2 inch transport chain

- Combination chain and vacuum belt transport

- Integrated modem

Features

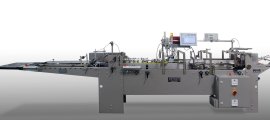

The Kohmann Giant F1440 Servo Window Machine has the highest productivity of any window machine in the industry and remains the most user friendly equipment for new operators. The features listed below are just some of the many time saving features of this machine.

Timed Belt Feeder

The timed belt feeder with Servo Technology operates the 1-, 2-, 3-, 4-up features and the oversized hardened cams give quiet, fluid movement of the lifters which reduce vibration and extend the life of the cam and cam follower. Lifters are made of a lightweight nylon material, reducing mass and enabling speed increases of up to 15% in comparison with ordinary belt feeders. In addition, the lifters are adjustable both forward and backwards making the feeding of irregular shaped cartons and material very simple. The feed gates with carrier supports have a nip distance of only 15mm (.6 inches) providing perfect carton control enabling higher productivity.

The timed belt feeder feeds folding carton material as well as corrugated up to 6mm thick.

1-up, 2-up or 3-up (optional)

Setting the cycle is easily carried out by inputting the relevant information into the PLC control panel. The direct drive of the cutting cylinder adjusts the gearing of the knife cylinder automatically.

Precise Squaring Section

The chain squaring section features a double spindle system ensuring the register chains remain absolutely parallel and that make ready and set up remain easy after all conditions even after years of running. The carton side guides and top guides are made of 5mm solid steel and are designed to withstand even the heaviest of jams. The guides are specially treated to protect against wear and corrosion. The rugged, 1/2 inch chain extends the life of the transport chain.

Conveying/Blank Transport

Blanks are conveyed from the chain section to the delivery section by the vacuum belt enabling optimum access and shorter changeover times. The suction table is split for two stream operation.

Doctor Blade Glue System

The doctor blade glue system with adjustable glue dams, meters the proper amount of glue and presents it where needed. The optimal coverage of the unit and its positioning above the stereo cylinder eliminates glue sling on chains and cartons and additionally provides easier access to the chain squaring and transport sections. In the event of a missing carton, a pneumatic cylinder lowers the glue counter roller.

Easy operation features of the glue unit for quick clean up allows the glue unit to slide entirely out of the machine. There is no glue pan to clean. Total clean up can be accomplished in less than ten minutes and glue consumption is dramatically reduced.

Other features such as the lowering of the suction table below the stereo cylinder prevents glue from contaminating the suction belts for missing blanks or cartons.

For ease in make ready the stereo cylinder is divided in the middle and the glue application stereos can be prepared outside the machine and then clamped to the stereo cylinder. When a job is finished, the mounted stereo can be stored for repeat orders.

Window Patching and Lining Station

The film is cut to length by a cross cut knife and film length is Servo Controlled to give infinite film lengths. Positioning the film relative to the carton in the running direction can be done while the machine is in operation by means of a handle. The cut film is picked-up and timed with the vacuum cylinder, which in turn is, timed to the glued carton. The glued carton and film are then combined under the vacuum cylinder. Blowing air and stripping springs adhere the window to the carton while it is transported at high speed to the delivery section.

Delivery

The Delivery Section is extremely versatile and even shingles irregular shaped blanks onto the wide transport belt. The height is infinitely variable via hydraulic adjustment. The gap of the shingle is variable via potentiometer. The delivery can be moved away from the machine to facilitate access to the knife station and for roll changes.

Materials

The vacuum cylinder is manufactured from a specially treated polyamide nylon - PA 6 material for longest wear and lifetime. Using this tested and approved synthetic material instead of steel not only provides both protection against corrosion of the cylinder surface and piping system but also significantly reduces weight, reduces energy requirements and extends the lifetime of the cylinder bearings.

Belt Driven

The main drive tooth belt system eliminates conventional sprockets, chains and gears and runs much smoother. The drive requires no maintenance, eliminates the central lubrication system associated with ordinary drives and makes worn and stretched chains a thing of the past. Registration is exact and consistent.

Programmable Logic Controlled

The Kohmann Giant F1440 Window Machine is equipped with a PLC control making the operation and monitoring functions much simpler. The PLC controls setting of the suction air control for the timed belt feeder, photocells for dust control and the lowering of the suction table when missing blanks are detected. A missing film control and double sheet detector which are also controlled by thee PLC are available options.

In addition, window/lining material cut-off length settings and many more parameters can be set with the new PLC control.

Most unique however are the numerous self-diagnostic and error detection controls on the PLC i.e., such as open safety doors and basic machine operation instructions available at anytime to the operator at a glance.

Ease of Operation and Maintenance

- Maintenance free drive concept.

- Online maintenance worldwide via modem.

- Accessible for adjustment and maintenance

- Micro fine adjustments of board to glue and film position while machine is running.

- Operator friendly.

- Minimum change over times.

- High productivity and unparalled quality.

- Computer driven production control system with automatic adjustment.

- Storage for data on more than 4,000 cartons for repeat orders.

Upgradeable

The Kohmann F1440 Window Machine can also be equipped with options designed for specific production requirements. Those options can be included at the time of purchase of can be retrofit as your production requirements change.

Specifications

Timed Belt Feeder

The timed belt feeder with Servo Technology operates the 1-, 2-, 3-, 4-up features and the oversized hardened cams give quiet, fluid movement of the lifters which reduces vibration and extends the life of the cam and cam follower.

Lifters are made of a lightweight nylon material, reducing mass and enabling speed increases of up to 15% in comparison with ordinary belt feeders. In addition, the lifters are adjustable both forward and backwards making the feeding of irregular shaped cartons and material very simple. The feed gates with carrier supports have a nip distance of only 15mm (.6 inches) providing perfect carton control enabling higher productivity.

The timed belt feeder feeds folding carton material as well as corrugated up to 6mm thick.

Blank and Film Size Ranges

| Format range, 1-stream operation | ||

|---|---|---|

| min. | max. | |

| carton length | 100mm 3 15/16" |

1230mm 48 12/16" |

| carton width | 80mm 3 1/8" |

1440mm 56 11/16" |

| Film length | 60mm 2 3/8" |

800mm 31 1/2" |

| Film width | 30mm 1 3/16" |

1130mm 44 7/8" |

| Format range, 2-stream operation | ||

|---|---|---|

| carton width | 705mm 27 1/8" |

|

| film width | depending on blank position | |

| film thickness | min. 30 microns | max. 300 microns |

| Production Speeds (mechanical possible) | 1 Stream | 2 Stream |

|---|---|---|

| 1-up operation cartons over 610 mm |

max. 200 pcs./min. | max. 400 pcs./min. |

| 2-up operation cartons below 610 mm |

max. 400 pcs./min. | max. 800/min. |

| 3-up operation (Optional) cartons below 385 mm |

max. 600/min. | max. 1200 pcs./min. |

| 4-up operation cartons below 270 mm |

approx. 600-700 pcs./min. |

approx.

1200-1400 pcs./min. |

| 3- and 4-stream operation: values must be multiplied accordingly | ||

| Floor Space Requirements | F1440 |

|---|---|

| Length | 5500mm/5800mm/216" |

| Width | 1900mm/2200mm/82" |

| Height | 1700mm/1800mm/66" |

| Total power requirement | approx. 34kW |

Applications

Examples of Kohmann Window Patching Machine Applications

The following examples are simple illustrations of typical applications.

Please call or e-mail for information pertaining to your specific needs.